sleeve, etichette adesive e booklet: la soluzione giusta per ogni esigenza

Le etichette adesive Indet sono la soluzione perfetta per rispondere alle tue esigenze di marketing, di promozione, di sicurezza e di sigillatura del prodotto.

Mettiamo a tua disposizione tutta la competenza e l’esperienza accumulate in 50 anni di presenza sul mercato, aiutandoti nella progettazione e realizzazione della tua idea creativa, trasformandola in una leva valoriale per comunicare il tuo prodotto e il tuo brand.

per noi le etichette sono molto più di semplici etichette

Per noi realizzare etichette non è un un lavoro, è creatività, passione, sperimentazione.

È esperienza che mettiamo in campo, ogni giorno da 50 anni e tramandiamo alle nuove generazioni con entusiamo.

In Indet non troverai solo un fornitore, saremo i tuoi partner e ti aiuteremo a dare il giusto volto ai tuoi prodotti.

Aumenta il valore del tuo prodotto con un’etichetta adesiva creata su misura per te

Qualità e know-how Made in Italy

Tutte le etichette adesive Indet sono made in Italy, di altissima qualità e garantiscono elevata resistenza e funzionalità per tutto il ciclo di vita del packaging.

Progettate per rispondere alle esigenze di ogni settore

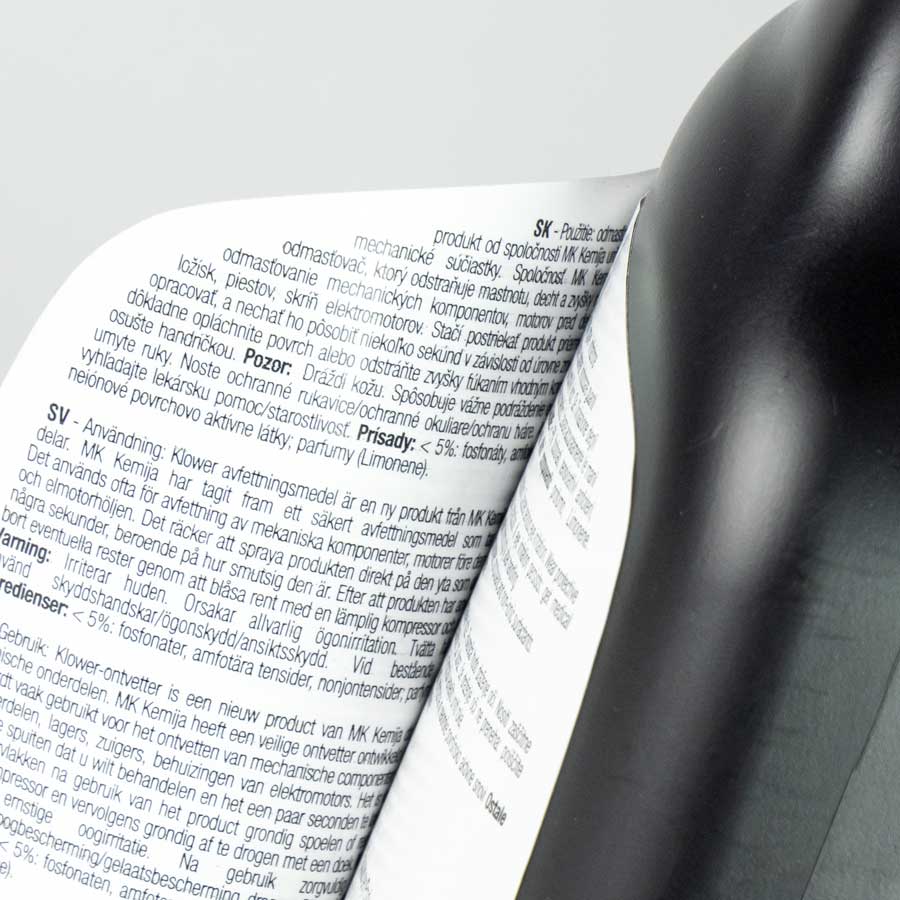

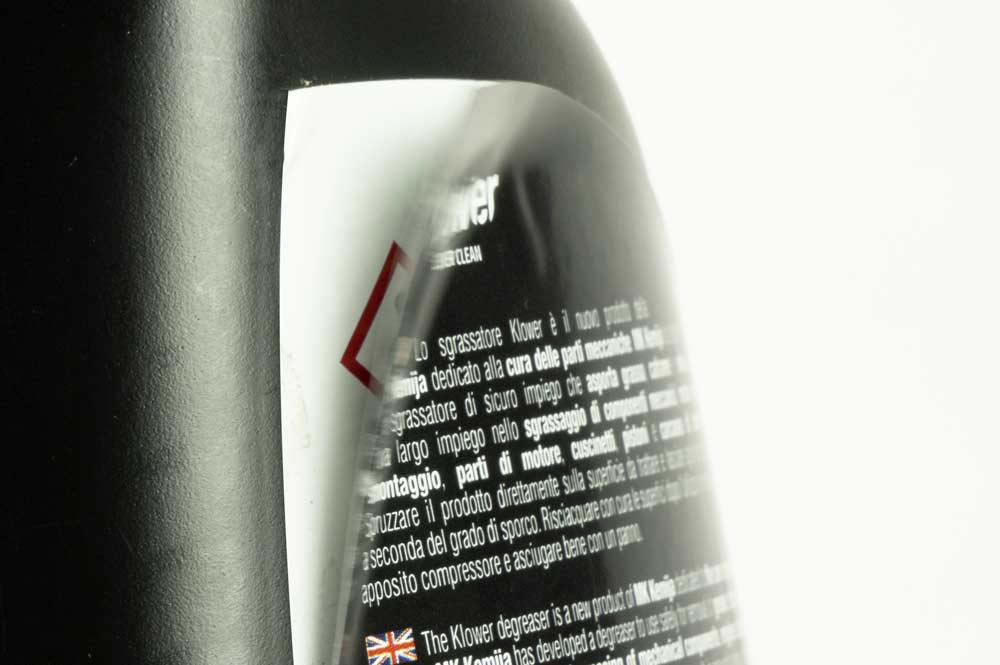

I campi di impiego delle etichette Indet sono vastissimi e potenzialmente illimitati: dal food & beverage alla cosmetica, passando per i prodotti chimici, meccanici ed elettronici.

Personalizzate in ogni dettaglio

Possiamo realizzare etichette adesive personalizzate permettendoti di scegliere tra diversi materiali come carta, plastica, poliestere, resina o alluminio sia bianche che colorate.

Creiamo etichette adesive davvero su misura

Siamo orientati al risultato e alla soddisfazione del cliente, a contraddistinguerci è la vocazione al prodotto e al problem solving.

Seguiamo i nostri clienti direttamente in modo professionale e proattivo creando soluzioni “cucite su misura” con il cliente e per il cliente, al quale offriamo non solo un prodotto ma un servizio, con un customer care dedicato e un’assistenza continua in fase di progettazione, consegna e nel post vendita.

Produzione di etichette adesive per ogni esigenza

Operiamo in un ambito in cui mercato e regole cambiano spesso repentinamente, proprio per questo interpretiamo con spirito dinamico il cambiamento, così da poterci adattare e far fronte alle esigenze di clienti di ogni tipo e per ogni packaging.

Cerchiamo non solo di risolvere i problemi ma di anticiparli, i nostri prodotti nascono da un collaudato background di esperienza nel settore, competenze tecniche e profonda conoscenza degli strumenti produttivi, che condividiamo e mettiamo a disposizione dei nostri Buyer, fornendo loro strumenti concreti, efficaci e funzionali.

Etichette personalizzate dal progetto alla produzione

Quando il cliente ci richiede di realizzare un’etichetta, porta con sé il pack o l’oggetto su cui dovrà essere applicata. Possiamo così partire da zero a strutturare, insieme, la dimensione e il materiale più adatto al prodotto o alla sua destinazione, realizzando poi il bozzetto grafico e verificandone la stampabilità.

Solo a questo punto procediamo al preventivo e partiamo con la produzione. La lavorazione richiede 10/15 giorni, in base al prodotto, considerando tutti i processi industriali di produzione, tabulazione e taglio atti a garantire il massimo della qualità.

Creiamo etichette adesive davvero su misura

Siamo orientati al risultato e alla soddisfazione del cliente, a contraddistinguerci è la vocazione al prodotto e al problem solving.

Seguiamo i nostri clienti direttamente in modo professionale e proattivo creando soluzioni “cucite su misura” con il cliente e per il cliente, al quale offriamo non solo un prodotto ma un servizio, con un customer care dedicato e un’assistenza continua in fase di progettazione, consegna e nel post vendita.

Produzione di etichette adesive per ogni esigenza

Operiamo in un ambito in cui mercato e regole cambiano spesso repentinamente, proprio per questo interpretiamo con spirito dinamico il cambiamento, così da poterci adattare e far fronte alle esigenze di clienti di ogni tipo e per ogni packaging.

Cerchiamo non solo di risolvere i problemi ma di anticiparli, i nostri prodotti nascono da un collaudato background di esperienza nel settore, competenze tecniche e profonda conoscenza degli strumenti produttivi, che condividiamo e mettiamo a disposizione dei nostri Buyer, fornendo loro strumenti concreti, efficaci e funzionali.

Etichette personalizzate dal progetto alla produzione

Quando il cliente ci richiede di realizzare un’etichetta, porta con sé il pack o l’oggetto su cui dovrà essere applicata. Possiamo così partire da zero a strutturare, insieme, la dimensione e il materiale più adatto al prodotto o alla sua destinazione, realizzando poi il bozzetto grafico e verificandone la stampabilità.

Solo a questo punto procediamo al preventivo e partiamo con la produzione. La lavorazione richiede 10/15 giorni, in base al prodotto, considerando tutti i processi industriali di produzione, tabulazione e taglio atti a garantire il massimo della qualità.

Siamo ecologici, siamo qualificati, siamo certificati

La competenza e l’esperienza maturata in 50 anni di presenza sul mercato si traducono in un processo di lavoro etico e corretto che ci ha portato a conseguire la certificazione ISO 9001:2015.

Per alcuni prodotti possediamo la certificazione FSC®, testimonianza del nostro impegno per la salvaguardia dell’ambiente.

Richiedi i prodotti certificati FSC®.

Il nostro vero valore aggiunto sono i nostri clienti

Per chi da un'etichetta vuole qualcosa di più

Le tecnologie, le regole del mercato e gli obblighi di legge cambiano repentinamente. Vuoi sapere come creare un'etichetta che rispecchi non solo i tuoi valori ma sia anche perfetta tecnicamente e dal punto di vista normativo? Leggi i nostri consigli, siamo qui per aiutarti.

Efficenza energetica energia rinnovabile aerotermica

Le birre artigianali crescono anche in creatività. Vivaci, fantasiose o vecchio stile, le etichette adesive sono il valore aggiunto dei produttori di birra italiani

Vuoi stampare etichette personalizzate per il tuo birrificio

Le birre artigianali crescono anche in creatività. Vivaci, fantasiose o vecchio stile, le etichette adesive sono il valore aggiunto dei produttori di birra italiani

Etichette autoadesive personalizzate per liquori

Etichette booklet: un mini-libro adesivo che offre più spazio alle informazioni dei tuoi liquori, senza perdere in qualità e rispetto dell’ambiente

Le etichette personalizzate sono laminate?

Le etichette adesive laminate fanno parlare il tuo prodotto al mercato. Un dettaglio in più per personalizzare anche tirature limitate

Per vestire il tuo prodotto, scegli lo Sleeve

Lo Sleeve termoretraibile è perfetto per il tuo prodotto in quanto aderiscono a 360° il contenitore, perché realizzate in film termoretraibile PET o PVC

Etichette secure booklet, l’ideale per l’industria farmaceutica

Secure booklet è un’etichetta autoadesiva che incorpora il prospetto illustrativo, fascicolato in modo da poter essere sfogliato comodamente, come un libricino.